New energy accessories, 5G communication accessories, electrical and electronic, medical devices, stainless steel kitchen and bathroom, steel office furniture.

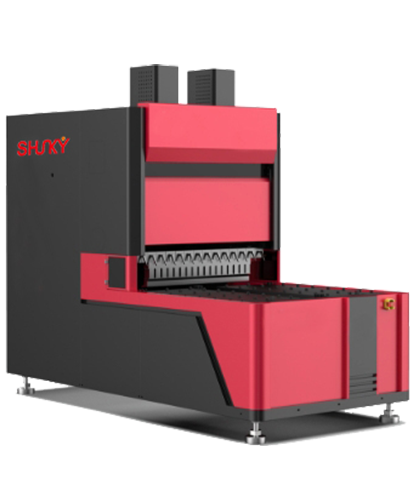

Applications: The intelligent flexible bending center is mainly used for automated, high-precision bending processing of metal sheets.

13585707741*24-hourWhatsapp/Wechat

The intelligent flexible bending center is a high-tech product developed and produced for the sheet metal industry to improve production efficiency, reduce labor intensity and enhance corporate image after 8 years of painstaking research and development. The product is self-developed from software drive, hardware circuit to mechanical structure, constantly optimized according to the industry characteristics of customers, from software operation to metal forming process, constantly explored and accumulated experience to meet the batch production of various special-shaped workpieces of customers, truly achieving cost reduction and efficiency improvement, and enhancing the competitiveness of customers' products. The customer base is spread across the country, and it has received unanimous praise from consumers!

EtherCAT bus control:

1. A true closed-loop system that never loses pulses.

2. 13-axis linkage at the bending center. Self-driven truss system, extended to up to 32 axes.

3. The movement between axes operates with zero time difference, truly multi-axis concurrent linkage.

4. The system provides an automatic rotation compensation calculation module for each cut of bending. The customer only needs to place the formed workpiece on the table, measure the left and right height of the bending edge that needs compensation, input it into the automatic rotation compensation calculation module, and then update the system rotation compensation parameters.

5. The system provides an automatic oil supply system and oil tank low oil detection prompt function, so users do not need to worry about the core components such as the equipment motor, bearing, lead screw being damaged or having their service life affected due to insufficient oil lubrication.

6. The system provides handwheel control function. Thanks to the anti-collision tool system, the system allows users to move each shaft to the desired position at will through the handwheel.

7. The gantry shaft has an automatic correction function. In the event of an abnormal power outage, it can quickly adjust to the same level to prevent the two motors on the same axis from being misaligned left and right.

Automatic die changing: It can automatically change the upper and lower bending diesthrough program control to meet the bending requirements of different angles and shapes,greatly reducing the product change time, especially suitable for small-batch, multi-variety production mode (i.e. "flexible manufacturing").

The use of servo motors and high-precision ball screw/rack and pinion drives, combined with precision guides, ensures extremely high repeat positioning accuracy for bending angles and dimensions (typically up to ±0.03mm level).

Support a variety of bending processes, such as shear-up bending and shear-down bending,to accommodate different materials and forming requirements.

The Strictly abide by the kinematic performance design, the use of large centrifugal force and steep elbow bevel design, so that the effective stroke at the bottom of the crushing chamber is larger, to ensure that the equipment has strong power.

Equipped with an intuitive graphical operation interface, operators can easily program and simulate the bending process.

The machine bed is made of integral welded structure and undergoes stress relief annealing to ensure stability and precision retention for long-term use.

The internal self-drive 7-axis truss system of the bending center system, the horizontal axis crossbeam is made of 160160 aluminium profile, with a total length of 6 meters, the crossbeam guide rail is installed as a whole 6 meters without interface, the guide rail runs more smoothly, the vertical axis is made of 80160 aluminium profile, with rack and pinion, the control system has an independent electrical cabinet and display screen, each axis can be independently controlled. It can work in coordination with the specific action template of the bending center to achieve automatic material picking, centering, bending and palletizing without manual operation.

| Device Model | System accuracy | Max. bending length | Min. fold height size | Max. folding height | Total mass | Total power | Fastest continuous bending speed | Max. processing thickness (iron plate/stainless steel/aluminum plate) |

Rated voltage | External dimensions (L×W×H) |

| 2000P | 0.001mm | 2100mm | 190mm | 177mm | 15000Kg | 40Kw | 0.25 seconds per cut | 1.5 mm / 1.0 mm / 2.0 mm | 380V | 5100mm×2650mm×3300mm |

| 1400X | 0.001mm | 1400mm | 190mm | 177mm | 10000Kg | 25Kw | - | 1.2 mm / 1.0 mm / 1.5 mm | 380V | 3330mm×1582mm×3800mm |

| 1000X | 0.001mm | 1000mm | 190mm | 177mm | 6000Kg | 16Kw | - | 1.2 mm / 1.0 mm / 1.5 mm | 380V | 3060mm×1500mm×2305mm |

Core configuration

| Configuration categories | Brand/Specification |

| Controller | Trimo, UK |

| Motor | He Chuan/Cui Ge, UK |

| Bearings | NACHI Japan |

| Bed | High grade cast iron |

| Guide rails/lead screws | Nanjing Process |

| Numerical control systems | Self-developed by Hanqi |

| Electrical components | Omron Japan |

13585707741*24-hourWhatsapp/Wechat